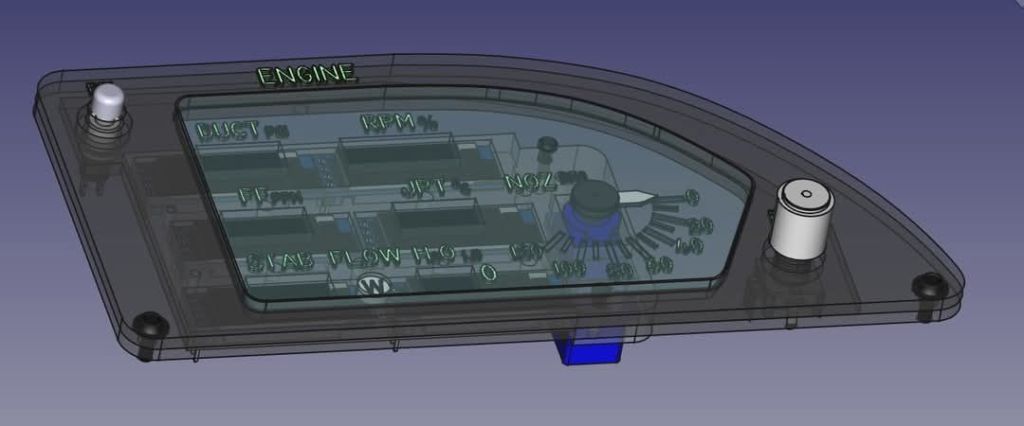

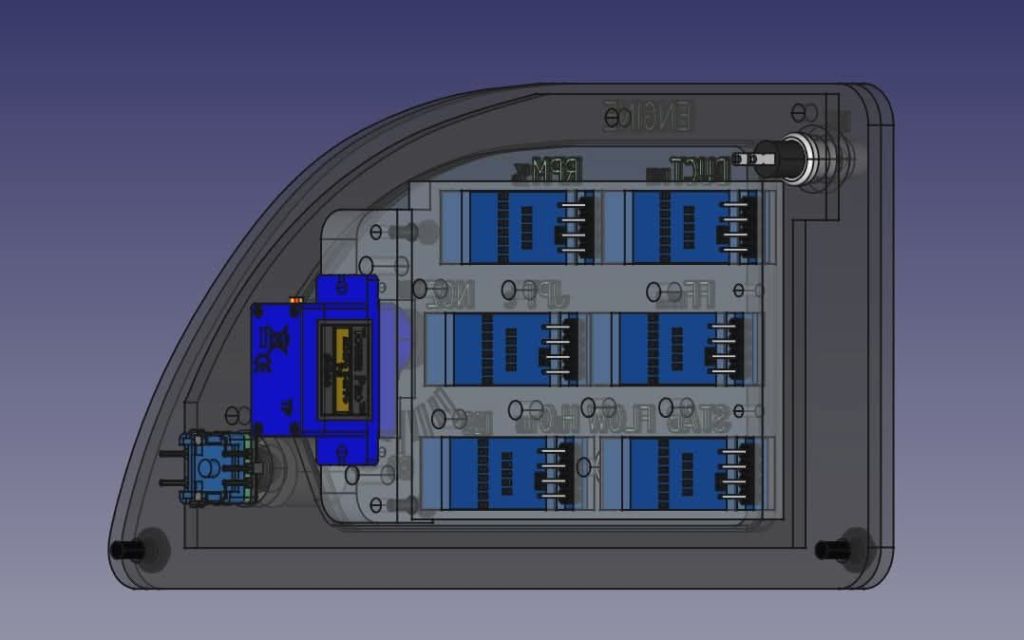

The engine panel contains 6 windows of numerical number drums which we simulated using 128×32 pixel OLED displays. It also contains an analog needle that depicts the nozzle position, a brightness knob, a BIT test push button, and a water injection indicator. We use a TowerPro SG90 micro servo for the analog indicator, and a potentiometer or rotary encoder for the brightness knob, and a simple momentary push button for the BIT test. We also use a 2mm laser cut piece of clear acrylic to cover and protect the display area. We use a 3d printed tray to hold the OLED displays and the mount the servo.